Add to Cart

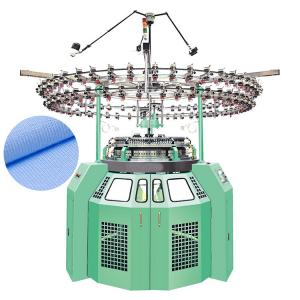

Single Jersey Body Size Knitting Machine Maquina Tejedora Circular Knit Slubbed Fabric

The Single Jersey Body Size Knitting Machine Maquina Tejedora Circular Knit Slubbed Fabric mechanical design is reasonable, high-speed operation is not easy to vibrate, and the stability is high. The edges and corners are made of special wear-resistant alloy steel, which has the function of wear-resistant and smooth. It is suitable for high-speed operation of knitting needles and precise runway. It is widely used in weaving high-grade fabrics.

Lead time:

| Quantity(sets) | 1 - 1 | >1 |

| Est. time (days) | 30-60 | To be negotiated |

Specification

Cylinder of Single Jersey Body Size Knitting Machine Maquina Tejedora Circular Knit Slubbed Fabric : lower needle cylinder, sinker. Cylinder of double jersey circular knitting machine: upper and lower needle cylinder.

If you need to order a cylinder, please provide the following information: model (which brand of machine), machine nameplate, needle of the machine, and sinker.

The types of take down system of the Single Jersey Body Size Knitting Machine Maquina Tejedora Circular Knit Slubbed Fabric are folding and rolling fabric machine,The open-width circular knitting machine is open width take down system.

Fabric Sample

The Single Jersey Body Size Knitting Machine Maquina Tejedora Circular Knit Slubbed Fabric can knit Fish scale cloth, sweater cloth, twill fabric, French fabric.

FAQ

Q:What is the standard of your company's suppliers?

A: The choice of suppliers is very important

1. First of all, it must be established for more than 10 years and have rich production experience;

2. Companies with imported brand new work machines;

3. The person in charge of the company has a motivated and responsible working attitude.

Q:lHow long is the normal use of your mold? How to maintain it daily? What is the production capacity of each mold?

A: All the sand casting molds of our company are made of aluminum molds, and the manufacturing cost is 50% higher than that of other counterparts. However, the cast workpieces have a well-proportioned shape and high smoothness, especially for some non-machined surfaces, the appearance is neat and clean, which is conducive to beauty. ; After casting, remove the attachments when not in use, store in a cool and ventilated place, lay flat without heavy pressure; can be used for more than 10 years.

Q:What is your production process?

A: Production process, casting procurement (300 sets of inventory) - rough inspection to eliminate various casting defects - storage - rough machining - sampling inspection to check whether the grade, hardness and density are up to standard - natural aging treatment (stored in the open air for more than 1 year) - fine Processing - storage area of finished products - assembly - testing technical parameters - debugging - packaging and delivery.